Oil, Gas and Mining Acoustical Consulting

in Queensland and NSW

Work with a team of seasoned acoustical engineers and consultants to manage noise, minimize costs and mitigate risks.

The Environment Protection Act (EP Act) and the Environmental Protection (Noise) Policy 2008 (EPP Noise) requires oil, gas and mining facilities to identify the potential impact of noise on environmental values and appropriately regulate noise activities and limit the potential for noise nuisance at sensitive receptors.

Under the EP Act, noise is considered a contaminant and noise nuisance is considered environmental harm. The EP Act also requires supporting information for a noise management plan, to enable efficient and effective response to noise management issues.

We support oil, gas and mining producers and operators with the following services:

- Noise Impact Assessments

- Complaint investigation and resolution

- Predictive modeling and noise control design

- Noise source diagnostics

- Representation at open house events as technical experts

- Occupational exposure studies

- Workplace noise maps

- Equipment diagnostics and mitigation

- Ongoing compliance monitoring

- Collecting and assessing multiple bids from noise equipment vendors

Noise Impact Assessments (NIA)

Predict noise levels from proposed or existing facilities at the nearest or most impacted occupied dwellings. Noise Impact Assessments (or NIAs) benefit facility owners in Queensland and Australia by assessing compliance with the Environment Protection Regulation 2008, proactively managing noise, and allowing for engagement with landowners and stakeholders.

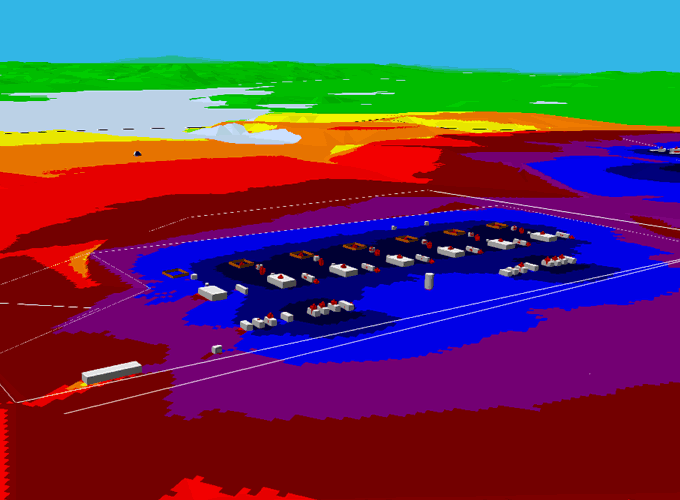

Our models simulate how sound propagates in your facility’s environment, which accurately predicts the noise levels at the closest resident or occupied dwelling. Based on your needs, our model can be designed to achieve regulatory compliance, pinpoint noise levels in any location, or eliminate guesswork from noise control design.

Our NIA clients are typically facility designers and operators looking for regulatory assurance and acoustic support in design or modification of their facility in Brisbane, Queensland or New South Wales.

Complaint Investigations

Determine whether an environmental nuisance has been caused, or a noise standard has been contravened by emission of noise. Patching Associates assess the complaint conditions and set up noise monitors at the facility and the affected occupied dwellings to capture the noise levels in the area.

In addition to measurements at the concerned receiver, we typically perform field reconnaissance (low detail measurements) to identify other noise sources in the area, and conduct detailed noise measurements at their facility.

Our precision equipment and unique process allows us to gather and analyze robust information that help you make informed decisions.

Noise Diagnostics

Quickly and accurately identify and measure individual noise sources at Oil & Gas and Mining facilities.

Our sound level meters provide data-rich information which we use to create a precise noise model. Determining the major facility noise sources, through noise diagnostics, results in representative operating conditions which reduces noise related conflicts and allows for targeted noise mitigation where necessary.

Clients see benefit in conducting diagnostics by knowing the sound levels attributed to their equipment accurately represent real-world data and their specific equipment, providing assurance that the resulting analyses are reliable and mitigation measures are appropriate.

Engineered Noise Control

Effective noise control solutions for Oil & Gas and Mining facilities can be a costly endeavor, especially when regulatory action is taken.

Our clients come to us to optimize noise control design to get the ideal level of performance to minimize the risk of costly complaints, delays or disruptions.

We identify the major noise sources at the facility, and complete a detailed contour map that captures sound emissions and their impact to the surrounding area.

Patching Associates’ accurate, and detailed modelling ensure noise control recommendations are fit for the purpose and avoid overdesign.

Patching Associates was very responsive in providing us with a service that accommodated our needs, enabling us to respond effectively to both our regulatory and landowner requirements.

Paul Dowell, Senior Commissioning Coordinator – Major Projects

Pembina Pipelines

Get a team of experts who knows your industry.

We’ve helped oil and gas companies with compliance for over two decades. Contact us today to ask questions or arrange a consultation.